- Main

- Applications

- For logistics companies and operators

For logistics companies and operators

Did you know that when the K2150 is installed, energy savings in warehouse lighting systems can reach 80%? Even if you have energy efficient light sources installed, we can reduce your energy costs several times further!

Nine unique advantages of the K2150 sensor:

1. It detects movements of a person or vehicle over an area of up to 3,000 square meters

2. It operates in warehouses from 3 to 30 m high

3. One sensor controls an inter-rack aisle up to 80 m long

4. It operates in freezing warehouses

5. It operates in warehouses with high air humidity (storage of vegetables and fruits)

6. It has additional outputs for connection to alarm systems or IP cameras in a warehouse

7. It can additionally measure the traffic intensity in the aisles for optimizing product layout

8. Real off-time delay can be just 30 sec due to high sensitivity (in comparison to 5-10 minutes for PIR motion sensors)

9. It has been included in the World Alliance for Efficient Solutions portfolio “1000 Most Promising Solutions”, Switzerland, since July 2018

How can energy savings reach 80%?

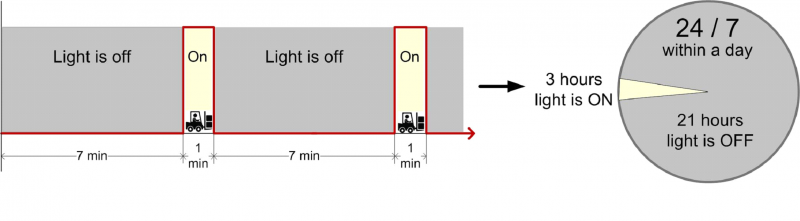

The figure below shows the result of measuring real traffic in an aisle of one of our clients. The forklift truck enters the aisle every 7 minutes and operates there for about 1 minute. When converted to hours, we get for the warehouse working round-the-clock:

Fig 1. How the traffic intensity in the warehouse affects lighting system automation efficiency

That is, the lighting in the aisle is used only 3 hours a day, and it is not necessary for 21 hours and it can be either switched off or its power can be reduced, for example, to 10% using the dimming function. For example, a 65W LED bulb in minimum luminous flux mode consumes only 4W! At the same time, a minimum, so called reference light level could be maintained in the aisle.

The payback period is usually 1 year!

At the above traffic intensity, one sensor saves up to 10,000 kW*h of electricity per year (24/7) and reduces CO₂ atmospheric emissions by 4 tons per year. For over a 15 year life cycle, one sensor saves up to 150,000 kWh of electric energy!

What does “Large K2150 sensor area” mean?

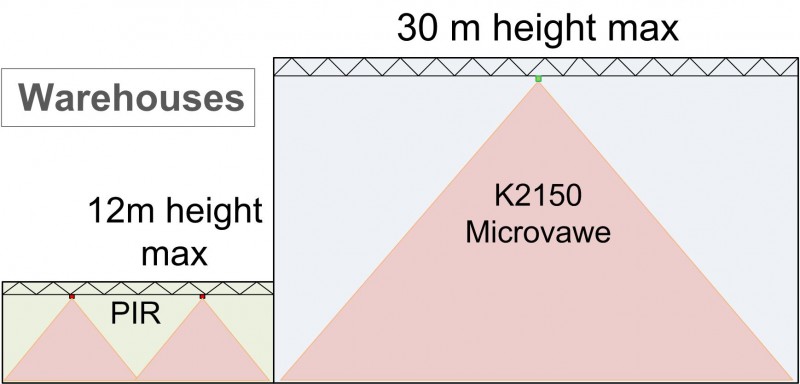

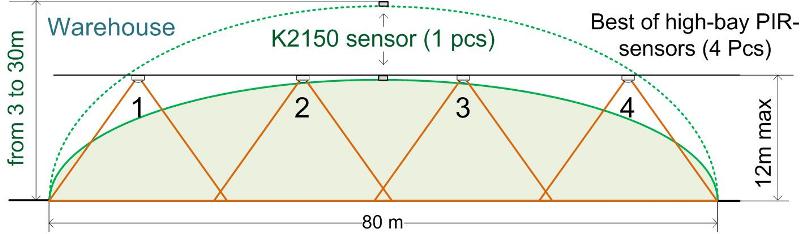

In figure 2, you can estimate the size of the K2150 sensor and its ratio to the infrared (PIR) motion sensor zones of the two world’s best brands.

Fig. 2. One K2150 motion sensor replaces 3–4 PIR motion sensors in an aisle 80m long

Now you only need one K2150 sensor per 80m aisle instead of 3–4 PIR sensors! Correspondingly, the length of cable lines and the cost of installation works, which make up a significant part of the total cost of automation, as they are performed at high altitudes with a multiplying factor, and require the rental of special equipment, are reduced by the same amount.

The working height of K2150 sensor installation is from 3 to 30 m!

At the same time, the installation height practically does not affect the size of the sensitivity zone: you control about 80m of an aisle or a long corridor (passage) with one sensor.

Fig. 3. Comparison of the working height of the PIR sensors and K2150sensor for warehouses

In areas with high land value, you can build higher warehouses, and our sensor will save up to 80% of the electricity consumed by the warehouse lighting system.

In higher warehouses, the lighting power is significantly increased, so the implementation of the “light on demand” principle brings maximum profit from automation.

K2150 sensor in freezing and chilled warehouses

Why is the installation of motion sensors particularly effective in chilled and freezing warehouses?

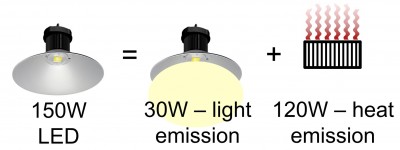

Even with the best LED bulbs, only 20% of the energy is used to radiate light (12–15% in reality) and 80% is used to generate heat. That is why a 150W bulb is not only a light source, but also a continuously operating 120W heater (150W x 0.8 = 120W).

Fig. 4. Distribution of the power consumption of an LED bulb for light and heat emission

For example, 100 bulbs with an output of 150W in your chilled warehouse without motion sensors are a 12kW heater that runs continuously and the warehouse chilling system must compensate for these parasitic heat emissions at all times.

So, in a chilled warehouse without motion sensors, energy is wasted twice: first by heating the air with lights, then cooling it with air conditioners to refrigerate to zero. And this happens 24/7… In the example described above (100 bulbs of 150W each) the financial loss of the warehouse owner is approximately €11,000 per year.

K2150 sensors will help to reduce this loss by 80%!

Why don’t even the best imported PIR sensors work in freezing warehouses?

Infrared motion sensors are optical sensors. In freezing warehouses, their focusing lenses are covered with frost and the sensors stop detecting movement.

Fig. 5. Infrared motion sensors do not work in freezing warehouses.

K2150 sensors use a different principle of motion detection, radio wave, and they have no optical lens, so they work well in chilled and freezing warehouses.

K2150 sensors can also be used in warehouses with high humidity such as those for vegetables, herbs, etc.

What else can the sensor do besides controlling lighting?

K2150 sensors have an additional alarm output which can be used as follows:

1. Connect to the warehouse alarm system

Fig. 6. Connection of the K2150motion sensor to the security system

If the warehouse is not open for service at night and on weekends, you can organize an additional line of security.

2. Connect to an IP camera installed in the same aisle as the sensor

Fig. 7. Connection of the K2150motion sensor to IP cameras

When a motion in an aisle is detected by the sensor outside working hours, the video image on the security post monitor (usually with an audible signal) switches from a multiplex picture to the full screen mode. A parallel video transfer from the alarm camera to the smartphone of the company owner or other trusted person can be also organized. This will allow you to identify theft of goods, including in collusion with the security service of the warehouse.

3. Measure the actual traffic intensity in the aisles

For this purpose it is necessary to connect sensors to WMS controllers of your warehouse by wire communication lines. This can also be implemented using IoT technology: to connect the sensor alarm output to the counter input with further data transfer to the cloud server (coming soon).

The radio channel sensor transmits the information through its controller to a cloud server where this information can be statistically processed and you will have an actual picture on the loading of your high-stack store areas. It is possible that since then the schematic for the shelf layout of the goods will change. WMS systems allow you to get information about how often goods are shipped from one or another aisle, but they do not “know” how long the warehouse employee is there, processing specific orders.

К2150 sensor's cost effectiveness (using the example of a warehouse)

The object is an actual warehouse with the 72х78 m area, 17 m height, and shelf storage of items. The length of the alleys is 68 m. The forklift drives through the alley every 7 min and stays there for about 1 min.

150 W LED fixtures without a dimming function, 216 pcs. The number of alleys is 18; the number of fixtures per alley is 12. The lights duty cycle is 24 hours per day.

Energy consumption without automation is 283,824 kWh per year.

Energy consumption with automation (3 emergency fixtures, 9 fixtures that get turned off by the sensor) is 97,567 kWh per year.

Savings: 283,824 - 97,567 = 186,257 kWh per year or 186,257 х 0,15 € = 27,938 € per year.

The modernization cost, including the installation cost, is approximately 24,000 €.

The payback period: 24,000/27,938 = 0.8 years.

Shortcomings with infrared motion sensors

Some shortcomings inherent to infrared motion detectors (PIR) can make your lighting automation costs inefficient and sometimes even useless. This is especially true for countries with warm/ hot climates. You should be aware of this. Learn more…